Why Cruise Lines are Switching to Nylon

In the high-traffic, high-humidity environment of a cruise ship, traditional metal hardware is a liability. Standard zamak, steel, and aluminum hooks eventually succumb to oxidation, leading to unsightly rust stains on cabin veneers and constant replacement cycles during dry docks.

Toughook offers a marine-ready solution designed specifically to solve the headaches of ship facilities managers and outfitters.

1. Total Immunity to Salt and Humidity

Unlike metal, our high-strength injection-molded nylon hooks are completely impervious to salt air and moisture. They are ideal for "wet zones" such as cabin bathrooms, spa changing rooms, and pool-deck lockers. They will never rust, pit, or corrode, ensuring they look as good on day 1,000 as they did on day one.

2. Enhanced Safety at Sea

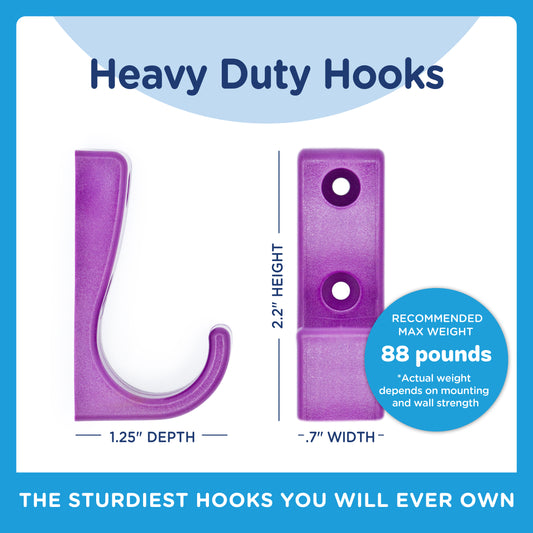

Rough seas and sudden lurches are inevitable. Traditional metal hooks with sharp profiles pose a significant injury risk during slips and falls. Toughooks feature a flatter profile with rounded edges and no sharp points, making them the safest choice for high-liability areas like Kids’ Clubs, family staterooms, and narrow crew corridors.

3. Lower Total Cost of Ownership (TCO)

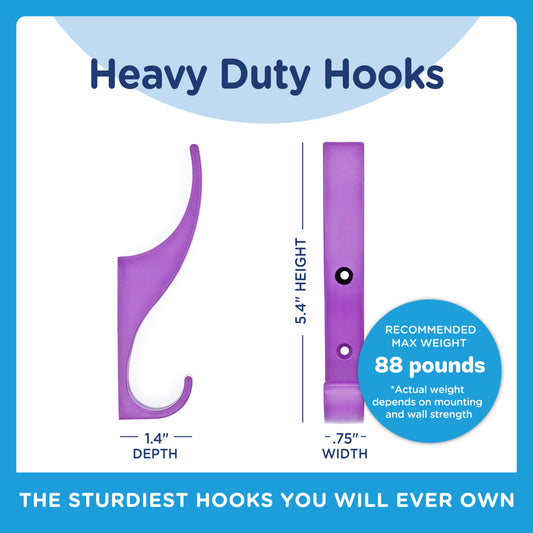

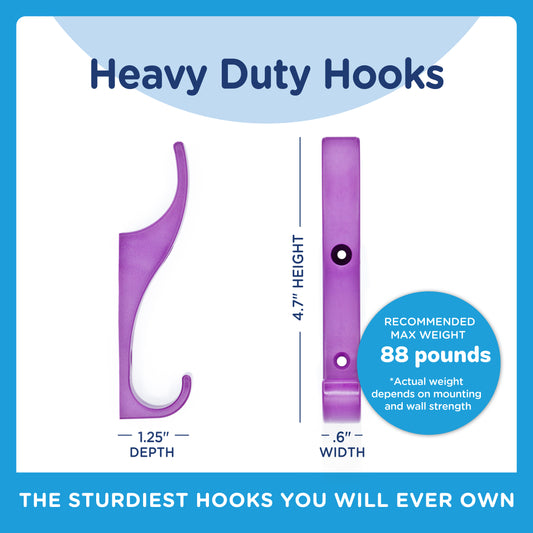

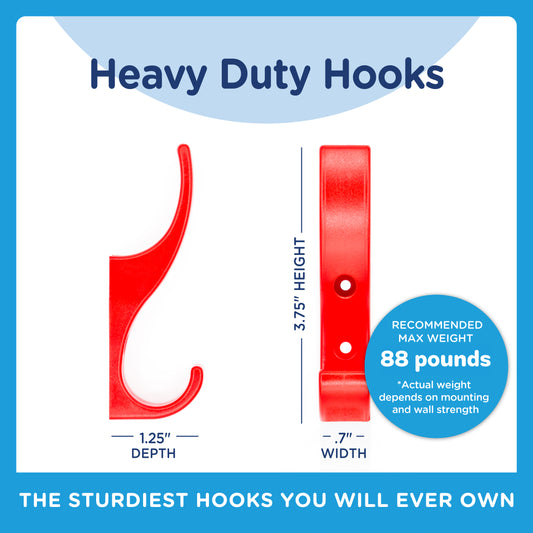

Cruise cabin hooks face abuse that hotel hooks never see—holding heavy wet gear, shore excursion backpacks, and makeshift laundry lines. Rated to hold up to 88 lbs, Toughooks are virtually unbreakable. By installing a hook that survives the heavy turnover of passengers, you eliminate the labor and material costs of constant replacements.

4. Branding and Zoning Flexibility

Move beyond generic chrome. With over 20 vibrant colors available, you can match your hardware to your cabin decor, or use color-coding for wayfinding in crew areas and activity centers.